What we do

OUR SERVICES

-

Supply

We supply a wide range of tungsten carbide tools for various fields of application.

Road milling, soil stabilisation, trenching, fibre and microfibre optics, disc or catenary excavation systems, foundation excavation, mining, horizontal drilling, stone grinding.

We can develop tools according to our customer's specifications. -

Assistance

We are able to support our customers with field service.

Thanks to the experience developed on site by our employees, we will be able to support you with targeted advice, helping you to choose the best tool for the job.

This will help you reduce operating times and lower operating costs. From diagnosing problems to supplying spare parts and repairs, we offer a complete service to reduce downtime and maximise operational efficiency.

Our goal is to ensure continuity and reliability by offering high-level technical support both on-site and remotely. -

Advice

The quality of the materials we use combined with our professionalism has helped us over the years to build relationships with the most important operators in various sectors, from road milling to the world of foundations and the agricultural sector.

With them, we have developed solutions tailored to the needs of individual applications, supporting them in their design processes for the benefit of their end customers. -

Planning

Power Drill offers a customised design service to develop advanced drilling solutions. With a team of specialised engineers and technicians, we design and implement customised projects according to our customers' specific needs, ensuring efficiency, safety and innovation.

We use state-of-the-art software and advanced design methodologies to optimise every step of the process, from material selection to equipment configuration. Our goal is to provide high-performance, tailor-made solutions that improve productivity and reduce operating costs.

info

ROCK HARDNESS CLASSIFICATION

LIGHT → Very soft and not solid rock, not stratified. Compression strength from o to 35 Mpa.

→ Rock Example Steatite | Argillite | Lignite

MEDIUM → Soft or medium / hard rock, medium. Layers Compression strength from 20-60 Mpa.

→ Rock Example Limestone | Caliche | Bauxite | Anthracite | Marl

HEAVY → From medium / hard rock to hard rock solid. Compression strength between 50-100 Mpa.

→ Rock Example Dolomite | Limoestone

COMPLICATED → Hard and solid rock with thick Layers. Compression strength _> 80 Mpa.

→ Rock Example Granite | Basalt | Iron minearls

SELECT THE BEST CARBIDE INSERT

FOR YOUR APPLICATION

info

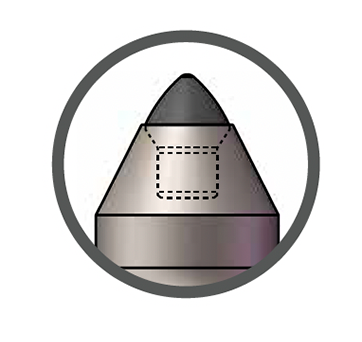

STRAIGHT CARBIDE PIN

Max toughness

Conditions: hard rock, crushed rock, cave rock, mixed soil rock.

Ideal for very strong cutting applications.

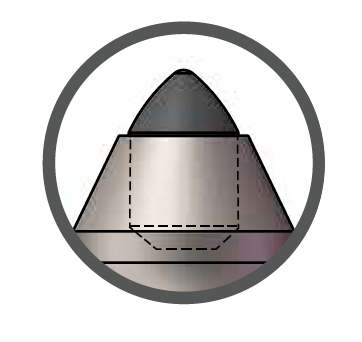

CAPSULE

Maximum abrasive resistance

Condition: soft or abrasive material.

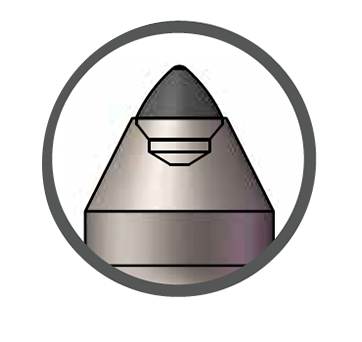

TAPERED CARBIDE PIN

Combination between a capsule pin and a straight pin

Conditions: Excellent for hard and abrasive cutting conditions.

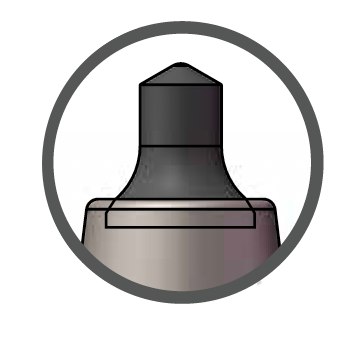

CARBIDE PIN

WITH FLAT BOTTOM

Maximum resistance to abrasion

Conditions: Softer and more abrasive material

Helps deflect material from the steel body reducing the wear caused by the abrasive material

Tebaide Media

Tebaide Media